Offset machines run at high speed so it’s important that papers are durable and sized correctly for this process to ensure proper ink lay down and hold-out without the inks picking off the surface. As a rule all papers for offset should be surface sized to ensure that less of the surface fibers pull off during the printing process.

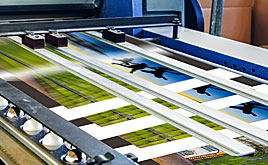

To better understand what this means, here’s how offset printing works: The paper passes under a series of rollers, two of which work together to put the printed impression on the paper. Before that happens, ink and water are applied to the printing plate, which itself is mounted on a roller. The ink binds to the part of the plate that contains design elements; the water is applied to the white space portion of the paper. Oil is mixed with the ink to ensure that the ink and water repel each other and there is no smearing or blotchiness on the finished product. The plate cylinder transfers, or offsets, the design onto a rubber blanket roller, which in turn transfers the design onto the paper.